Product features

The advantages of piezoelectric inkjet printers in the field of signage printing

High-definition printing

• Compared to traditional signage equipment, piezoelectric inkjet printers can achieve physical resolutions up to 600DPI, with other resolutions like 180, 300, 360, etc., available for selection.

Less prone to clogging

• Whether it's for oil-based inks for permeable substrates or UV-curable inks for non-permeable substrates, because they are solvent-free, even if not used for a long time, the print heads are less likely to clog.

Environmentally friendly

• The oil-based and UV-curable inks used in piezoelectric inkjet printers have no VOC emissions, meeting environmental protection standards.

Large Format Printing

• A single printhead offers a variety of printing widths including 32.4mm, 54mm, 71.8mm, and 108mm, and the printing speed is not affected by adjustments in rows and height, allowing for even larger printing widths through multi-head seamless splicing technology.

Fast Printing Speed

• Current piezoelectric printhead technology can reach a maximum firing frequency of 100K, with a single head printing 600*600DPI images at speeds over 200 meters.

Device Features

Easy to Install Anywhere

• A sturdy and durable all-stainless steel design that can be installed on almost any production line.

Easy and Convenient Operation

• With a user-friendly interface and software guidance, operation is straightforward.

Ink Cost Management

• The software includes an advanced ink cost management function, which can precisely calculate the ink cost for each print.

Database Printing

• The standard Easyprint printing software includes a database printing function, compatible with TXT, EXCEL, CSV, and other data packets.

Powerful Network Communication Capabilities

• Equipped with a network protocol communication interface, it can connect with ERP, MES systems, and various specialized software for complex labeling applications.

Intelligent Ink Level Management

• Low ink level alarms prevent stoppages due to ink shortages, supported by the device's audio-visual alarm lights for onsite management.

One-click Purge

• The one-click purge function empties the ink system when changing ink types or during long periods of inactivity.

Automatic Machine Cleaning

• For long-term inactivity, the automatic cleaning function makes it easy to clean and maintain the entire machine, combined with a specialized printhead moisturizing solution to keep the device in optimal condition.

Integrated Circuit Controlled Ink Path System

• Whether it's an intelligent siphon ink supply system or a negative pressure ink supply system, both are controlled by ARM integrated circuits, offering exceptional performance, stability, and powerful functionality.

FWS Fault Alarm System

• Standard audio-visual alarm lights and clear prompts through the human-machine interface for device faults, allowing for quick repairs with the maintenance manual, minimizing downtime, reducing the need for expertise, and improving repair efficiency.

Convenient Information Editing

• Utilizes a 13.3-inch 1080P high-definition industrial touchscreen, allowing direct editing of various texts, graphics, one-dimensional and two-dimensional barcodes, and variable data on a new user interface, or upload print content directly via USB interface or network protocol.

Ink Homogenization Awakening System

• Prevents sedimentation in pigment inks (like white ink), avoiding print quality issues or printhead clogs, eliminating the need for ink discharge and cleaning during medium to short-term shutdowns.

Technical Parameters

Printhead Type

• Industrial grade high-definition piezoelectric printhead

Printing Direction

• 360 degrees in any direction

Number of Printing Lines

• Unlimited, within the printhead printing height range, arranged as desired

Printing Mode

• Single or continuous printing

Printing Speed

• 0-600 meters/minute

Ink Types

• Oil-based ink, water-based ink, UV-curing ink

Printing Content

• Fixed and variable text, images, various codes, database

Ink Colors

• Black, white, various spot colors, ultraviolet or infrared visible

Printing Fonts

• Any font supported by the Windows system

Printing Software

• Easyprint multi-function printing system

Data Interface

• Network interface, USB interface, RS232

Operating System

• Windows 7 64-bit and above

Communication Interface

• Gigabit Ethernet

Power Requirements

100-240 VAC 50/60Hz

Control

• 13.3-inch high-definition industrial touchscreen

Total Power

• 100-850W

Humidity Requirements

• Below 85% non-condensing

Ambient Temperature

• 0° C to 50° C

Barcode Types

• EAN8, EAN13, UPC-A/E, CODE 39, CODE128, EAN128, GS1 DataBar (including 2D composite), DataMatrix, QR, PDF417, etc.

A Rich Ink System

Offers a variety of inks in terms of properties, performance, and colors

• Special inks for various metals

• Special inks for various paper substrates

• High adhesion inks for varnished surfaces

• Inks suitable for glass, ceramics, and other special materials

• High adhesion inks for PE, BOPP, and other plastic substrates

• Industry-specific invisible security inks

• Special inks resistant to alcohol wiping and immersion

• A variety of colors including white, red, yellow, blue, green, etc.

• Inks with special requirements such as low odor, steam resistance, low migration, etc.

• Inks customized according to customer requirements for performance, color, etc.

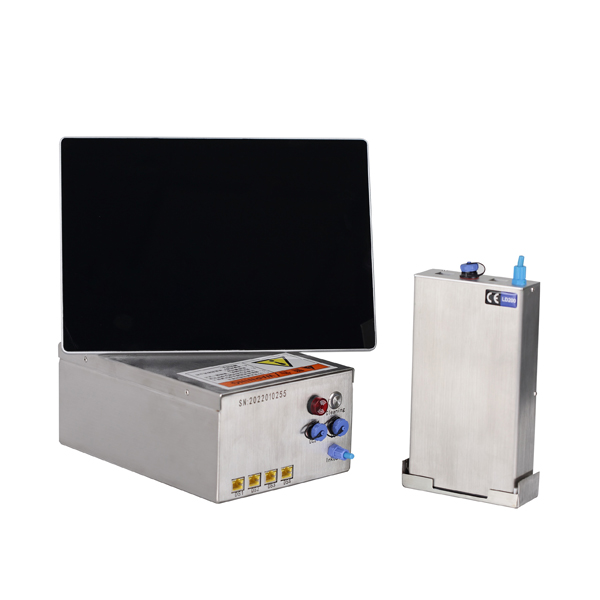

LS-LD SERIES HIGH-DEFINITION UV INKJET PRINTER - Intelligent Siphon Standard Model

Meets the demands of 24/7 continuous production, balancing product performance with low usage costs, and can be quickly deployed across various production lines for high-precision digital coding and marking. Features several patented innovations in the intelligent siphon ink supply system, which, unlike traditional siphon systems, is more intelligent, user-friendly, and flexible while retaining the strong stability of the siphon ink supply system. The equipment is equipped with advanced technologies such as fault pre-warning, multi-level liquid management, intelligent awakening circulation, ink exhaust, quick modularization, one-click purge, and one-click whole machine cleaning.

Printing parameters

Model | LD50 | LD70 | LD70PLUS | LD100 | LD200 | LD300 |

Print height | 32.4mm | 72mm | 72mm | 32.4mm | 54mm | 54mm |

Physical resolution | 300DPI | 180DPI | 360DPI | 300DPI | 600DPI | 600DPI |

Ink droplet size | 3PL | 35/50PL | 12/35PL | 7PL | 7PL | 5/7PL |

Speed | 110m | 50m | 50mm | 110m | 220m | 300m |

Resolution | 600*300DPI | 180*180DPI | 360*360DPI | 600*300DPI | 300*600DPI | 300*600DPI |

*Final speed depends on the printing content and frequency

Application scenarios

Flexible Functionality Expansion

The LD series reserves the possibility for multi-printhead expansion, with a single ink path capable of supporting up to 4 print head modules, currently offering 6 different types of print head modules for selection. Adding new print head modules can be completed in minutes. Multiple ink paths can be controlled by a single software suite through cascading, allowing for expansion up to 254 print head modules.

The LD series reserves the potential for functional upgrades, with upgrades between different device models requiring only the replacement of the print head module, achieving upgrades in printing height, precision, and speed with minimal investment. Stainless steel and aluminum printhead brackets allow for multi-dimensional fine adjustments, enabling 360-degree printing in any direction.

Combining many advantages and features in one, with an industrial-grade body design, exquisitely compact

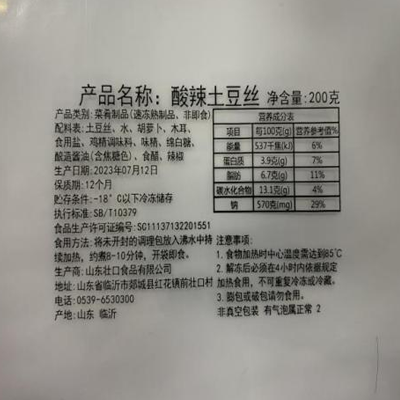

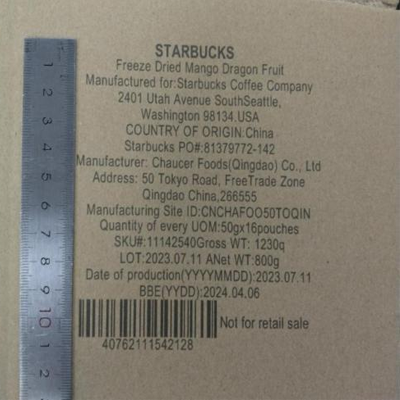

Sample display: