Main Features:

1. LS-G540 is a high-precision variable data printing device, meeting the market's pursuit of printing precision, using Japan's Ricoh G5 (600DPI) industrial piezoelectric printhead, making the printed content clearer and more beautiful.

2. The overall elevation of the printhead is electrically adjusted, no external air source is needed onsite. The ink output of the Ricoh G5 printhead nozzles can be adjusted via software, changing different ink waveforms according to the actual onsite materials for stronger adaptability; each row of nozzles is independently controlled, facilitating the alignment of each row for finer print effects.

3. Modular positive and negative pressure high-precision ink supply system, ensuring extremely stable ink supply during operation, continuous operation 24/7 without affecting print quality.

4. The entire machine adopts a modular design, facilitating daily operations and maintenance, making it more intuitive for customers to understand the machine's structure and principles, also facilitating onsite installation and debugging.

5. The main control system uses self-developed industrial control boards and software, reliable quality, controlling every action of the printing process.

6. High precision (±0.01kpa) positive and negative pressure ink path system: Negative pressure is responsible for holding the ink, ensuring no ink shortage or overflow at the nozzle, the stability of the negative pressure ink supply directly determines the quality of the print effect and the long-term stable operation of the device; multi-layer protection for negative pressure for better ink path stability. Positive pressure is used for automatic ink cleaning of the printhead, too high positive pressure can damage the printhead, too low positive pressure won't clean the air in the ink path properly, the correct positive pressure is a guarantee for the printing effect. Large ink tank low ink alarm, two-level ink cartridge alarm system uses audio-visual alarms, large ink tank low ink has a buffer design, even if low ink alarm occurs, the device can continue to work, making ink addition more composed.

7. The power system uses international first-line brand high-performance power supplies. Providing stable power for system operation, the driving force for device operation, also a guarantee for the print effect, separate control for each part of the power supply, modular design, beneficial for equipment maintenance.

8. Windows 10 system industrial tablet computer, for running coding software, editing and processing data, equipped with a gigabit network card, ensuring data transfer rate and data security.

9. Modular printhead components, industrial design, can quickly and conveniently adjust the parallelism and perpendicularity of the printhead to the platform, the high precision adjustment of the bracket and printhead is also a prerequisite for ensuring print effects.

10. Variable data editing software features anti-repeat code function, barcode beautification function, meets level requirements, supports multiple special code types for printing, can be customized and developed according to different customer software systems and devices.

Technical Parameters

Serial Number | Name | Parameters | Remarks |

1 | Printhead Resolution (dpi) | 600dpi vertical | Physical Resolution |

2 | Printing Height | 54MM | Single Printhead |

3 | Printing Resolution (dpi) | 200-1200dpi | Paper Feed Direction DPI |

4 | Printing Speed | 0-85 meters/minute | Printing speed depends on the actual printing material, ink droplet size, effect requirements, etc. |

5 | Printing Content | Text, images, one-dimensional codes, two-dimensional codes, anti-counterfeit codes, databases, Han Xin codes, dot matrix codes, lines, squares, etc. | Can develop functions according to actual customer requirements |

6 | Printing Software | LS-V3.0 Variable Data Editing Software | Self-developed, can be customized and developed in conjunction with different customer software systems and devices |

7 | Number of Printheads | 1 printhead |

|

8 | Distance from Printhead to Product | Within 0.5mm-3mm | The closer the distance, the neater the edges of the printed content and the better the effect |

9 | Working Method | Downward Printing |

|

10 | Supporting Equipment | Single sheet or roll printing | In conjunction with a page separator/conveyor/rewinder/customer production line |

11 | Printing Mode | Paging or continuous printing | Normal production requires page printing, one product triggers one print per time |

12 | Printing Length | Print template 2m | Maximum template length, special requirements can be customized |

13 | Ink Types | UV Ink | LED UV Curing |

14 | Ink Colors | Black, white, red, blue, green, etc. |

|

15 | Ink Supply Method | Positive and Negative Pressure Ink Supply |

|

16 | Cleaning Method | Positive Pressure Cleaning |

|

17 | Ambient Temperature | -10-40°C |

|

18 | Environmental Humidity | 5-90% |

|

19 | Printing Materials | Non-porous (PVC, OPP, BOPP, PET, coated paper, metal, printed surfaces, etc.) and porous materials (paper, cardboard, wood, etc.) | Customer effects are based on actual print samples |

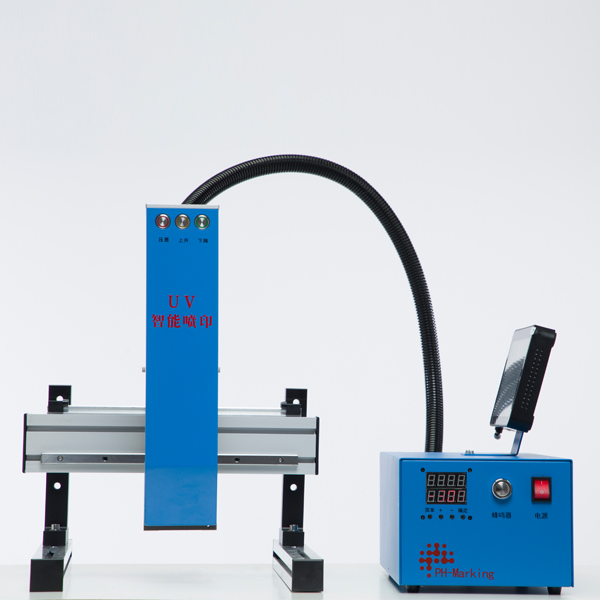

20 | Optional: Plasma Treatment Machine | Material Surface Treatment | Used to improve the surface tension of materials, making the ink adhere more closely to the material, improving the adhesion of the printing ink |

Sample display: