Technical Specifications

The fully automatic image measurement instrument is designed for planar and three-dimensional measurement, suitable for industries such as PCB, LCD, sheet metal, aerospace, etc., for large stroke measurements. It uses a mobile bridge structure,

Yadeke precision-grade parallel linear guide rail, incorporating the most advanced design concepts in the industry, with the most perfect design and the strictest production process control, to ensure the accuracy and stability of the machine.

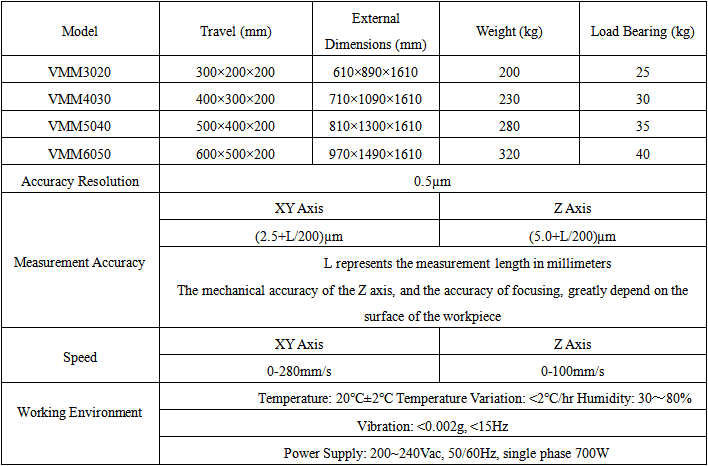

Basic Parameters

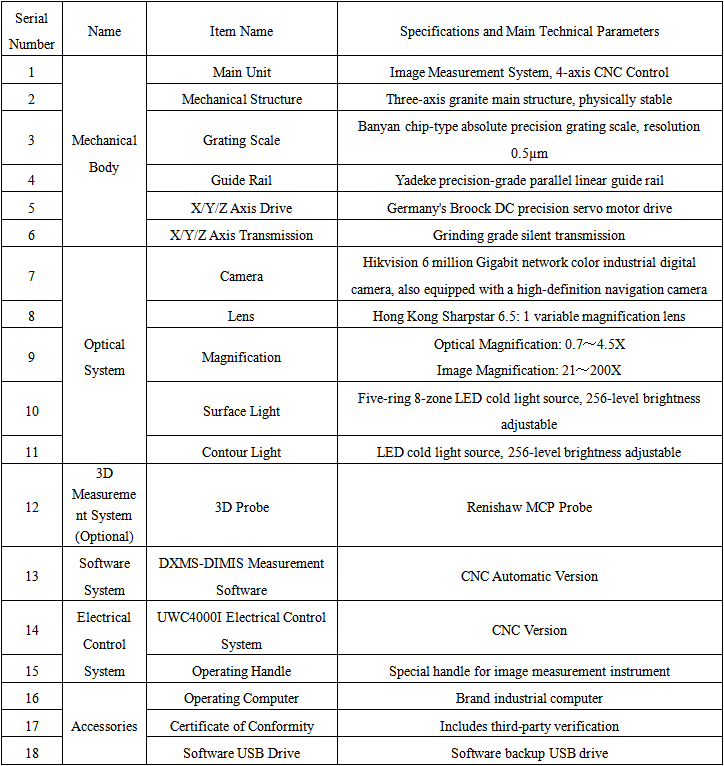

Configuration List

Instrument Features

Mobile bridge structure, large travel fully automatic measurement, four-axis CNC control.

Precision granite base, high accuracy, and good stability.

Fully automated control via mouse and handle, simple and easy to use.

German-imported open-type grating scale, high accuracy, and good stability.

Electric variable magnification optical lens, capable of variable magnification measurement.

Programmable 5-ring 8-zone ring-shaped surface light source, LED contour light source.

Automatic focusing for height measurement, equipped with a contact probe.

DXMS-DIMIS fully automatic image measurement software.

Provides various standard configurations and can be customized according to requirements.

Basic Measurement Functions

1. Geometric quantities that can be measured: Points, lines, circles (maximum, minimum, and average), arcs, splines, ellipses, rectangles, quadrilaterals, slots, R corners, rings, spacing, distance, point groups, etc.

2. Construction: Center points, extreme points, endpoints, intersections, lines between two points, parallel lines, perpendicular lines, tangent lines, bisectors, centerlines, merging, contour segmentation, radius drawing, three-line inscribed circles, two-line radius inscribed circles, etc.

3. Image measurement tools: Drawing points, nearest edge points, focus points, circular frame points, best edge points, nearest points, overall extraction, multi-segment extraction, texture segmentation, multi-segment texture segmentation, electronic calipers, quick organization of circles, open c

4. Form and position tolerances: Straightness, roundness, position, parallelism, perpendicularity, inclination, concentricity, etc.

5. Coordinate system: Fixture positioning coordinate system, point line, two points X, two points Y, three points, two lines, image registration coordinate system; translation, rotation, manual adjustment of the coordinate system.

Programming and Automated Operations

1. Can generate tasks for fully automatic batch measurement and support automatic and manual interactive operations.

2. The lens can be manually varied, and no recalibration is needed after magnification changes.

3. The light source is automatically controlled, supporting automatic lighting.

4. Supports automatic control of each segment of the surface light (five rings eight zones) and contour light.

5. Can quickly autofocus, measuring focus height.

Output and Data Statistics

1. Can output Word, Excel, TXT reports, and AutoCAD files.

2. Supports real-time output to Excel templates, customizable templates.

3. Output can be limited to the data from the last run of a task.

4. Running a task automatically generates an .rst format file, documenting detailed information about the task's execution.

5. Print after completion: Tasks can be directly printed upon completion.

6. Output task data to a file: The results of task execution are output to a text file, with data from tasks of the same name output to the same file.

7. Data can be automatically output to a csv file in a specified directory based on the task name, facilitating unified analysis of results for similar workpieces. SPC statistical function, importing rst files for effective quality control.

8. Element property area, real-time display of data for the element currently being measured.

9. Element over-tolerance area, categorizing elements as normal, over-tolerance, and not measured, among others.

Other Enhanced Features

1. SPC: Analysis and control of measurement data.

2. Panoramic Scan: Select any area for image scanning and stitching.

3. Drawing Comparison: Load drawings to compare with measurement data.

4. Test Sieve: Automatically scan a test sieve, generate tasks, and directly analyze and output results.

5. Temperature Compensation: Calculates expansion coefficient based on the difference between environmental and standard temperatures for more accurate results.

6. Focus Height Measurement: Measuring height differences by focusing.

7. Automatic Contour Extraction: Extract specified contours given start and end points.

8. Edge Display: Display image edges for quick edge inspection.

9. Crosshair Extraction Mode: Multiple display modes, including cross, grid, circle, grid, for quick comparison.

10. Navigation: Image navigation, similar to an electronic map, for quick positioning.

11. Import CAD Drawings: Import DXF drawings, interchangeably import and export with CAD for graphic processing.

12. 3D Display: Display the three-dimensional state of an image.

13. Multilanguage Switching: Simplified Chinese, Traditional Chinese, English, Japanese, Korean, etc.

14. Lens Calibration: Automatic lens calibration eliminates the tedious steps of full calibration.

15. Variety of shortcut operations, comprehensive common shortcuts make the software easier to use.

16. System settings include various detailed setting options.